Items 1 - 40 of 110

Art.Nr: 94G018-BU

1.245,00 € *

415,00 € per 1

Art.Nr: 94G036-BU

840,00 € *

280,00 € per 1

Art.Nr: 94G036

Graco progressive pump G1 Standard - for grease - 2 litres - 24 VDC - without control - with scraper

595,00 € *

Art.Nr: 215202A335-Ö

399,00 € *

Art.Nr: 94G006-V

Price on request

Art.Nr: 215201A327-V

738,60 € - 870,60 € *

Art.Nr: 215201A325-V

841,35 € - 976,17 € *

Art.Nr: 215201A330-V

844,60 € - 1.100,50 € *

Art.Nr: 215201A335-V

215201A335-V - BEKA MAX - Progressive Pump EP-1 - Without control unit - 12V/24V - 8 kg - 1 x PE-120

977,03 € - 1.195,72 € *

Art.Nr: 21753005101-V

844,20 € - 1.338,88 € *

Art.Nr: 21753005401-V

21753005401-V - BEKA MAX - Progressive Pump EP-1 - With control unit - 12V/24V - 2,5 kg - 1 x PE-120

1.046,00 € - 1.603,54 € *

Art.Nr: 21753005201-V

1.124,70 € - 1.727,84 € *

Art.Nr: 21753005801-V

1.257,59 € - 1.878,05 € *

Art.Nr: 94G007-V

Price on request

Art.Nr: 94G008-V

Price on request

Art.Nr: 218531110-V

420,15 € - 525,62 € *

Art.Nr: 218511144-V

Price on request

Art.Nr: 218541151

918,53 € *

Art.Nr: G25R809-V

450,40 € - 640,00 € *

Art.Nr: G25R810-V

580,00 € - 800,00 € *

Art.Nr: KFGX1FAXXXXX99+912-V

846,80 € - 1.061,73 € *

Art.Nr: KFGX1FX1XXXX99+924-V

846,80 € - 1.736,47 € *

Art.Nr: KFGX3FAXXXXX99+912-V

1.205,06 € - 1.694,37 € *

Art.Nr: KFGX3FAXXXXX99+924-V

1.205,06 € - 2.347,13 € *

Art.Nr: KFA1+912-V

Price on request

Art.Nr: KFAS1+912-V

Price on request

Art.Nr: KFAS10+485-V

KFAS10+485-V - Vogel / SKF Progressive Pump KFAS10 - 120 up to 370 Volt - 1,0 kg - With control unit

Price on request

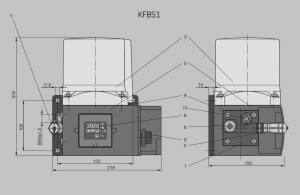

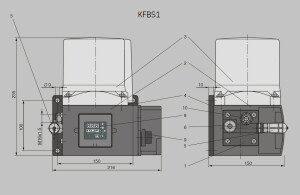

Art.Nr: KFBS1-6-S1+912

Price on request

Art.Nr: KFBS1-6-S1+924

Price on request

Art.Nr: 96G000-V

646,85 € - 1.360,00 € *

Art.Nr: 96G038-V

807,50 € - 1.402,50 € *

Art.Nr: 96G052-V

935,00 € - 1.445,00 € *

Art.Nr: 96G199-V

1.062,50 € - 1.445,00 € *

Art.Nr: 96G172-V

1.147,50 € - 1.572,50 € *

Art.Nr: MULTI2AE-V

Price on request

Items 1 - 40 of 110