Items 1 - 40 of 63

Art.Nr: 171-210-051

288,60 € *

Art.Nr: 171-210-052

288,60 € *

Art.Nr: 171-210-054

288,60 € *

Art.Nr: 171-210-061

384,79 € *

Art.Nr: 171-210-062

412,22 € *

Art.Nr: 171-210-063

288,60 € *

Art.Nr: 171-210-064

288,60 € *

Art.Nr: 171-210-065

288,60 € *

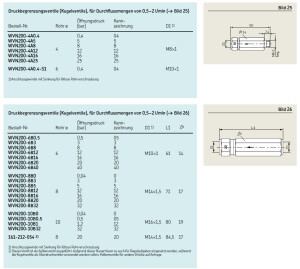

Art.Nr: WVN200-10E6-V

172,80 € - 214,16 € *

Art.Nr: 24-0455-2370-V

35,56 € - 39,51 € *

Art.Nr: 24-0455-2617-V

24,08 € *

Art.Nr: 24-2720-1004-V

419,73 € - 574,48 € *

Art.Nr: 24-2720-1102-V

574,47 € - 1.218,02 € *

Art.Nr: 24-2581-2650-ZH

Price on request

Art.Nr: 24-2581-2656-ZH-V

1.001,46 € - 1.402,05 € *

Art.Nr: 24-2581-2652-ZH

2.123,29 € *

Art.Nr: 24-2581-2151

Price on request

Art.Nr: 24-2583-2526

1.081,29 € *

Art.Nr: 24-2583-2516

898,90 € *

Art.Nr: 24-2583-2517

977,08 € *

Art.Nr: 24-2710-1012-V

1.332,94 € *

Art.Nr: 24-2713-1250-V

2.208,33 € - 2.453,71 € *

Art.Nr: 24-2714-4570-V

24-2714-4570-V - Vogel / SKF Quantity limiter SP/SMB14 - For oil - 25-75 l/min. - With monitoring E1

3.109,66 € *

Art.Nr: 24-2703-0250-V

767,52 € *

Art.Nr: 24-2703-7300-V

955,15 € *

Art.Nr: 24-2703-8250-V

955,15 € *

Art.Nr: 24-2703-6250-V

1.009,84 € - 1.122,07 € *

Art.Nr: 24-2706-0730-V

1.810,85 € *

Art.Nr: 24-2706-8730-V

1.998,47 € *

Art.Nr: 24-2706-44570-V

1.998,47 € *

Art.Nr: 24-2708-0050-V

448,01 € *

Art.Nr: 24-2708-7055-V

635,60 € *

Items 1 - 40 of 63