Sinntec - Your supplier for SKF, Beka Max, Graco and Delimon central lubrication technology

Our company has been supplying European industry, trade and agriculture with high-quality industrial pumps and accessories for pumping all kinds of liquids for years. With our know-how in the field of industrial pumps, we focus on the highest level of consulting quality. We will be pleased to assist you in the selection of suitable products.

The company SINNTEC Schmiersysteme GmbH is your Europe-wide acting partner when it comes to SKF lubrication (formerly Vogel lubrication). Consultation, delivery and installation of your central lubrication, as well as everything concerning the topic of lubrication, you get from us from one source. Our team of specialists will be happy to answer any questions you may have about the application and system design of lubrication, so that you as a customer are always well advised on questions about central lubrication and the entire subject of lubrication systems. Competent advice paired with high qualities, prompt shipping incl. low costs and available alternative products - should your desired article not be available - make us your competent partner in matters of SKF central lubrication.

Central lubrication for industry

The company SINNTEC Schmiersysteme GmbH is a Europe-wide operating company in the field of central lubrication as well as workshop equipment. We support the European industry in the implementation of central lubrication systems of any kind as well as their installation. Our sales team will advise you on the selection of components for the central lubrication system as well as on the pressure calculation. When calculating the pressure for a Beka Max central lubrication system, it is important to ensure that the input and output values of the components used for central lubrication are optimally matched.

Our company is active in the following industries, where it advises, supplies and installs systems from the field of centralized lubrication:

- Lubrication Technology units for steel mills

- Central lubrication units for metal processing plants

- Grease lubrication for heavy industry

- Lubrication Technology for the commercial vehicle industry

- Cutting ring fittings for the beverage industry Central lubrication for wind power plants

Furthermore, we supply the trade, agriculture, commerce and industry with high-quality pumps for the transport of acids, alkalis, diesel, oil, water, gasoline, AdBlue® and other media. The customer receives after a detailed consultation, all components necessary for the transport and storage of liquids. We provide you with various platforms for obtaining quotations, information on individual components and complete systems on our website. We are happy to make our extensive knowledge available to you and your employees. A competent sales team completes this service.

The pump MKU2-KW3-22003+428 is designed for oil and has an internal control unit, which works time or cycle controlled. The plastic tank of this gear pump for Lubrication Technology is robust and has a capacity of 3 liters. We supply SKF spare parts and replacement components for this component. The unit is installed in processing machines and is very robust as usual for SKF pumps.

The flow rate of 0.2 liters per minute is sufficient for an SKF pump. The unit is installed in various processing machines. The built-in control of the central lubrication allows the SKF piston pump to work independently from the mains. The MKU11 piston pump is the smallest version of SKF's centralized lubrication systems in Germany. This pump is the most suitable pump of SKF especially from the installation dimensions. This pump has a flow rate of 0.1 liters per minute. With the pump, a pressure switch is installed by us and also a bird pressure gauge. With this manometer you can control the output pressure of the gear pump. Also for this pump, you can get the gear pump and pressure switch as spare parts as an example. The other components of these SKF gear pumps are very robust and intended for many years of operation. With this SKF unit of a central lubrication is also the smallest lubrication solution.

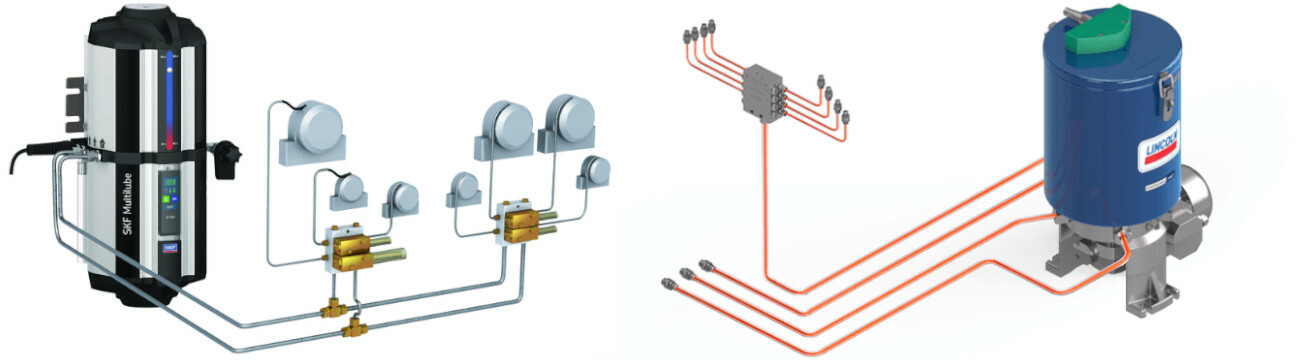

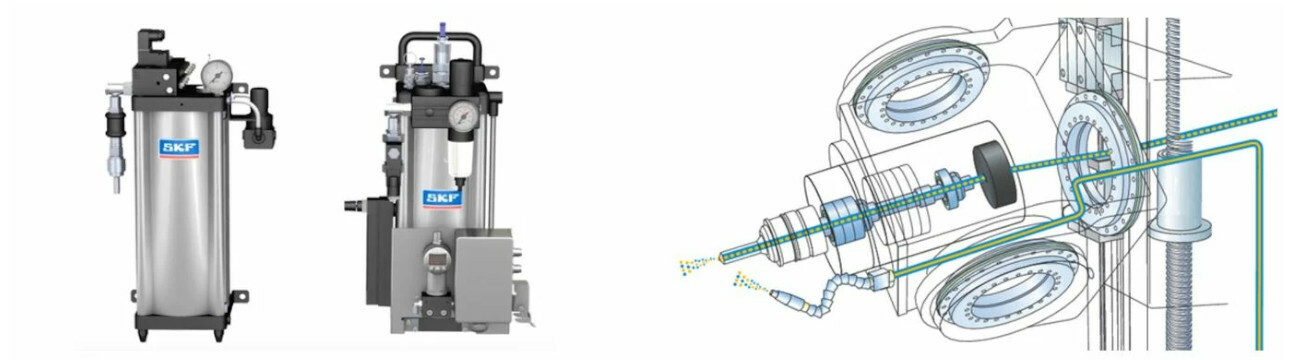

Lubrication Technology for industry SKF central lubrication / Vogel central lubrication.

This central lubrication unit MFE5-BW7 from SKF has a 6 liter steel container. This container was first produced by the Vogel company and has proven itself over the years. The individual components of this pump made by SKF in Germany have certain unique features. The special feature of this pump is the internal structure. The central lubrication pump has a 230/400 volt motor and a Vogel gear pump made by SKF in Germany. This gear pump delivers 0.5 liters / minute of oil and is especially designed for rugged applications. These applications can be in the steel industry as well as in the chemical industry. The level indicator always shows the user the exact level of oil in the tank.

Central lubrication for commercial vehicles Central lubrication and steel industry.

A vehicle pump KFU2-30+924 from SKF Germany is to be used for fluid grease. This fluid grease pump (intended for central lubrication) from SKF Germany is a robust pump for use on excavators, trucks`s, agricultural machinery and other commercial vehicles. The reservoir holds 2.7 liters and includes a level indicator. The Sinntec piston pump is driven by a 24V motor. We can offer you this pump with a Sinntec control unit. There are different installation features to be considered.

For agricultural machines, the Sinntec control unit is installed behind the pump. This control unit then takes over the complete operation of the pump. This gear pump is built in Germany and has been installed in vehicles for more than 10 years. A stable Sinntec central lubrication system is required for pumping fluid grease. This central lubrication system impresses with its technically sophisticated design and functionality. A stable container is important for the Sinntec central lubrication system, as the various applications often do not allow a bird plastic container. This Sinntec central lubrication system delivers from 0.2 to 0.5 liters per minute and is intended for use on processing machines. The installed components of the central lubrication system are all of European production and all have various safety certificates.

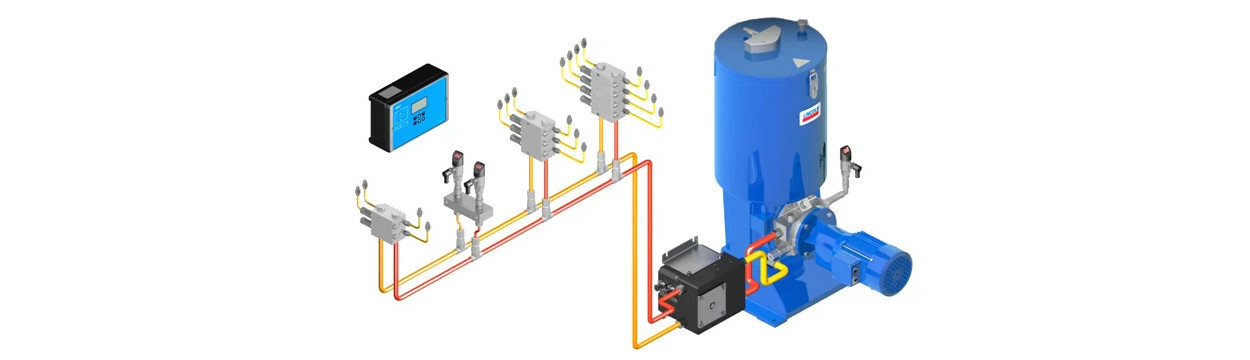

The block distributors of the Lincoln company from Germany are built so sturdily that they are used on vehicles and on industrial plants. These Sinntec progressive distributors or Sinntec block distributors have a fixed output quantity. The individual outlets can be connected to each other. When installing the progressive distributors, make sure that the internal pistons are installed in a horizontal position. This type of installation of the Sinntec distributors is important, as otherwise the distributors could "hook". Different versions are available. On the one hand designs in steel or in stainless steel. On the other hand, these Sinntec central lubrication distributors are available with 6 to 24 outlets.

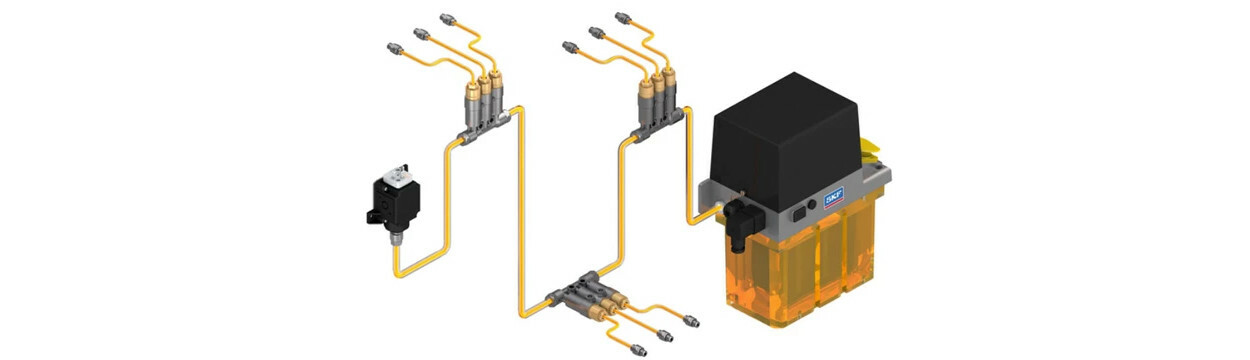

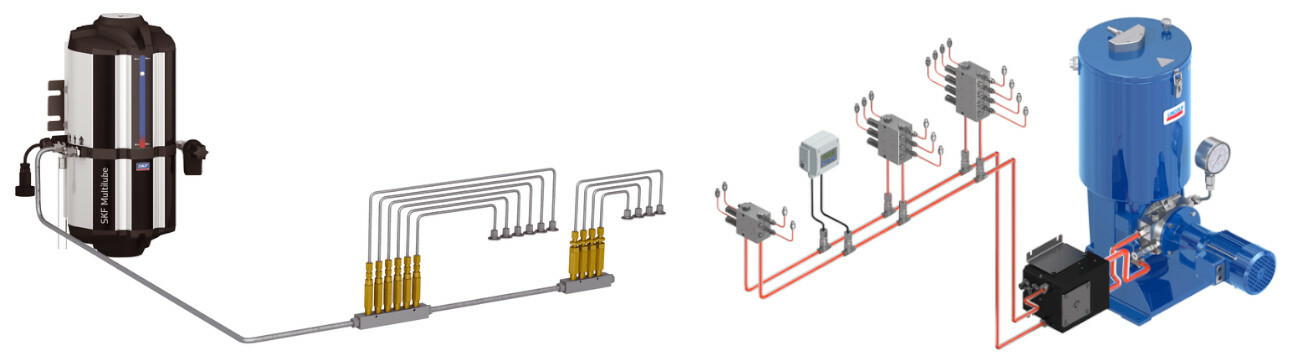

SKF progressive distributors VPBM, VPG and VPKM

An SKF distributor for central lubrication can also be built and supplied as a disc distributor, as in this example. The special feature of this unit is that the individual discs of this Vogel distributor can be assembled in different ways. With the product of the SKF company it is important that the individual lubrication points receive exactly the same amount of lubricant. For this purpose, different types of discs of the distributor are necessary. When installing in commercial vehicles, it is important to ensure that the lubrication points get exactly the right amount of lubricant. Also these distributors can be assembled up to a quantity of 24 lubrication points. This product is also a quality product of Sinntec. A segment distributor from Sinntec Germany can be installed in individual machines or as a single Sinntec component in a large industrial plant. The individual segments are interchangeable, so that the dosing quantity of the distributor can be changed as required during operation. Up to 840 cmm/stroke are possible with the various metering quantities. This opens up various possibilities for lubrication. The individual segments of a central lubrication system are interchangeable and thus variable. These distributors are suitable for oil or grease, depending on viscosity. The products have been a standard in the industry for years and are installed in many industrial machines.

The inlet manifold of the can be equipped with different metering elements. The delivery pressure of the SKF pump can be between 15 - 35 bar. The products from the range of SKF single line distributors from Germany are suitable for oil and fluid grease. Germany also supplies the suitable connectors for your Vogel central lubrication system. Company Sinntec central lubrication systems sells metering units series 321-G. In the most different sizes. The metering units vary between 0.3cc, 0.6cc and 0.10cc per stroke. The best result is achieved with oil recommended by Sinntec lubrication technology. And to achieve a perfect result, the single-line distributors need the lubricant oil.

With a progressive distributor, it is possible to install electronic monitoring. This proximity switch or cycle switch is mounted in the outlet side of the distributor. This cycle switch works with 24V and monitors the function of the distributor. At the pump, the progressive distributor is also connected through a grease line. The proximity switch is connected to an external control and counts the individual pulses of the SKF pump. As soon as a certain number of pulses of the cycle switch have been made, the control knows that the bird distributor is working properly. we can show you the different connection possibilities.

At Sinntec, you can get the 350 series single-line distributors in a wide variety of designs. Sinntec spare parts can be delivered as quickly as possible. In order to use the single-line distributors productively, please use the lubricator oil. We have them in stock with different metering elements. With delivery per stroke you get the single line distributors in the sizes from 0,1ccm; 0,2ccm; 0,4ccm to 0,6ccm. The 350 series centralized lubrication distributors are available from Germany in screwed and plug-in versions. The company has many different metering elements in stock for the 320 series distributors.

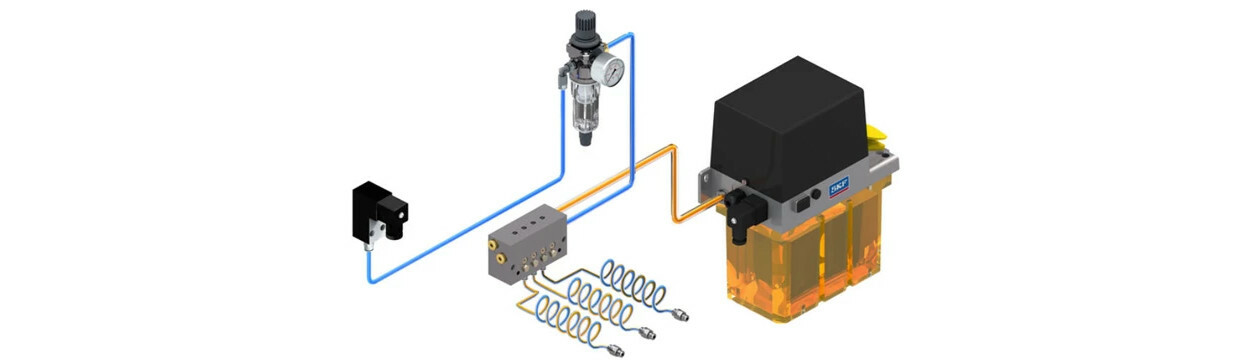

Oil lubrication with a pump pressure relief valve.

Sinntec Schmiertechnik manufactures the metering distributors as 321-L series elbow fittings, directly for connection to a lubrication point, for the thread dimensions of: M8x1 keg, M10x1 keg and R1/8" keg. To get the screw connection for the connection dimensions on the hose, use the dimensions of Ø 4mm or Ø 6mm accordingly for it. The dosing quantities per stroke are 0,03 cm³ 0,06 m³ and 0,10m³. Vogel carries the T- elbow fitting of serial number 312-T, which is good to use for small narrow spaces. The company Germany stands for quality. The hose connection is available in diameter 4mm and 6mm. Different thread sizes are suitable for it with among: M8x1 keg, M10x1 keg and also R1/8 keg.

The grease guns that lubricate the chains work with fluid grease or oil. With a Sinntec directional valve, the direction of the oil or grease can be controlled. With a progressive distributor and the Sinntec pump, the design of the components is critical to the service life. The metering valves from Vogel work with oil, which are driven by a pump with oil. The proximity switch from Sinntec is comparable to a cycle switch. A float switch in a Sinntec pump is responsible for checking and reporting the oil level in the piston pump. The Sinntec pump is also available as an ex pump. In this case, an Ex motor is installed on the component, which in combination with a progressive distributor from Sinntec makes the lubrication system run.

Lubrication with a pump is very important in central lubrication. The pump used consists of a gear pump and various parts, which you can also get as spare parts. Sinntec tries to give the customer the possibility to lubricate with oil. With a Sinntec central lubrication system, the lubrication system is provided with a barrel pump or a piston pump. The various gear pumps are built into piston pumps. A lubrication system of a central lubrication always includes a Sinntec pump as well as various other components, such as a Sinntec pressure switch or a block distributor. In industry in Germany, oil is often used as the lubricant in lubrication systems. Bekamax and Sinntec supply this market. For oil lubrication and chain lubrication, a grease pump is also used. The minimal quantity lubrication is a refined part of the central lubrication technology.

The stainless steel distributor is not always necessary for this Lubrication Technology system, but if the grease and oil supply with components of SKF in food processing plants, this is important. The central oil supply with oil pumps allows a reasonable oil lubrication. Beka spare parts such as a pump element or a PE 120 are immediately available. The grease pumps are in stock as well as throttle valves and level switches. A central lubrication system includes grease metering as well as plain bearing lubrication. The KFG1-5 lubrication system includes a progressive distributor. Automatic lubrication with oil is also suitable for vehicles. A DS pressure switch is important for oil lubrication because it monitors the pressure. In the central lubrication systems in industry, bearing lubrication is important for production operation. A lubrication with a piston pump and a block distributor is available in 12V or 24 Volt. Oil lubrication as an offer can be requested from our sales department. A chain lubrication as well as the minimum quantity lubrication can be supplied by Voegele.de or www.voegele.de. The central lubrication technology is so far advanced in the today's time that also ex pumps can be used. The chain lubrication systems work with oil and a piston pump. The ex pump delivers the lubricant through piping directly to the individual lubrication brushes, creating a thin film of oil on the chains. Pressure relief valves create a specific outlet pressure in a central lubrication system. The plastic pumps as piston pumps are equipped with a pump element and a motor.

Level switches, a proximity switch, cycle switches and a distributor must also be used. A throttle valve works best with oil in such a system. The electric oil pump is installed on equipment as a 24V or 220 V variant. The gear pump and various other components must be handled with care. Dealers are eager to answer your questions about lubrication technology quickly and competently. Lubrication systems are installed worldwide. Stainless steel pumps can be combined with stainless steel distributors. The whole is rounded off only by fittings and hose lines. Vögele Germany as well as the sales department of SKF in Germany are the contact for your questions and suggestions in the field of Lubrication Technology.